installing the new cam bearing ... use assembly lube, set the bearing in the hole firmly with your thumbs, one in the cam chest, the other from the top through the lifter block hole

use the butt end of a wooden hammer to start setting the bearing

after I gave it a few light taps with that, I put the thrust washer on the OLD CAMSHAFT and inserted it into the bearing.

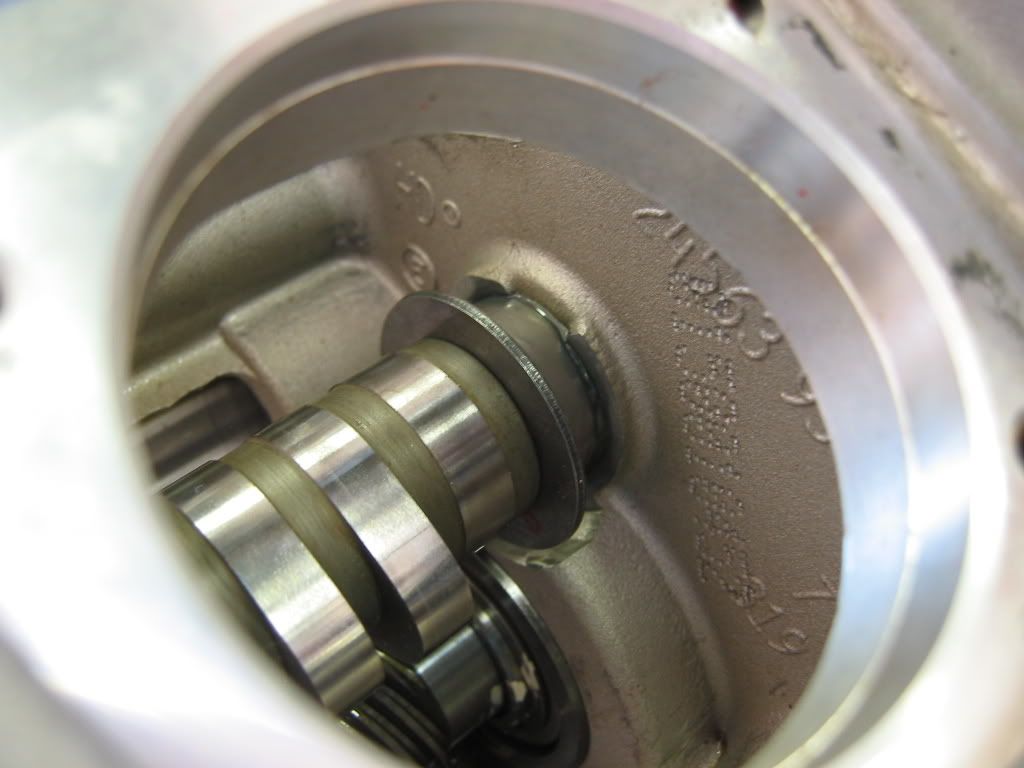

Then I hit the end of the camshaft with a rubber dead blow hammer .... I drove it in until I thought that it was seated, checked it with a flashlight

you can BARELY see the lip of the seat when the bearing is in.

after the bearing was set, I put the cam cover back on and checked the camshaft endplay .... this assured me that the bearing was fully seated. My measurement came back eggzactly to what it was prior to removal of the INA bearing ..... .010 inches ..... I was a HAPPY CAMPER

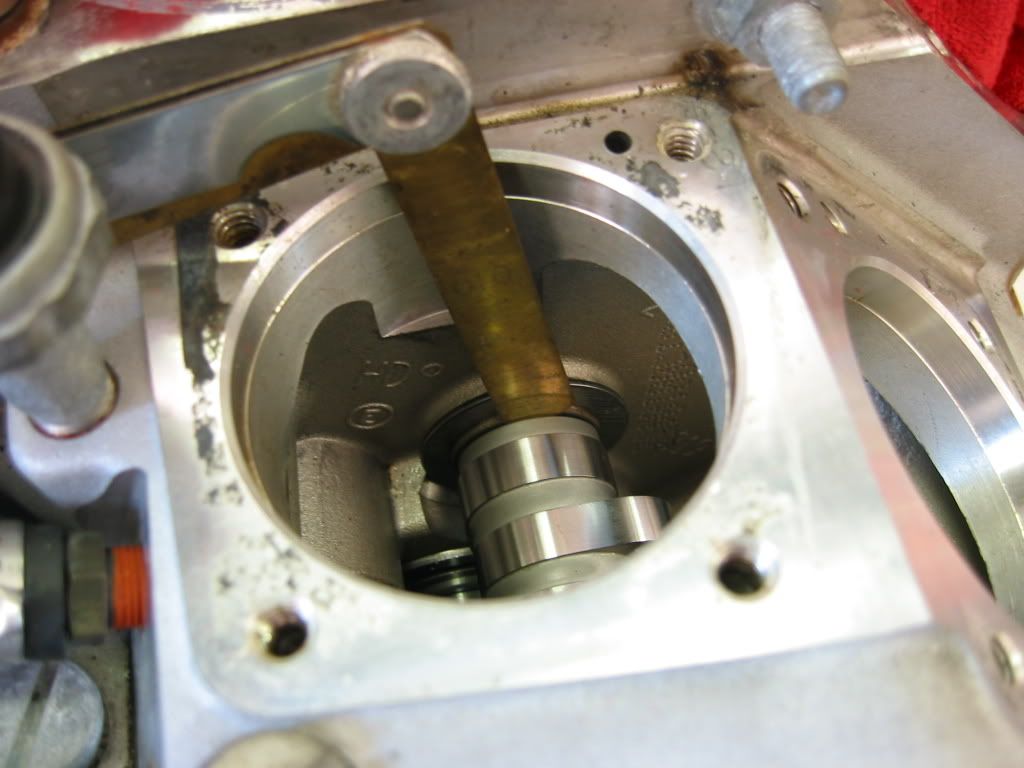

then I removed the cam cover and the gasket, and installed the reed breather valve, EASY EASY, put some assembly lube on it and slide it in the hole, how easy is this stuff !

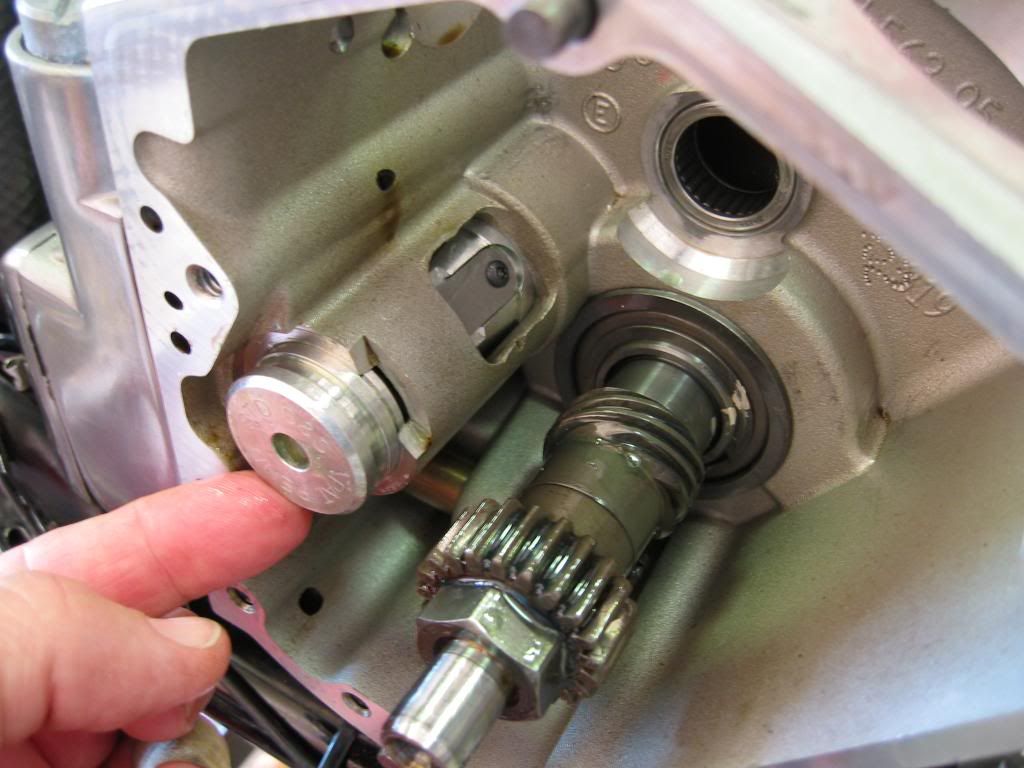

then I installed the camshaft ..... now I have to tell you..... it took me 20 minutes OR MORE to find the dayum timing mark on the pinion gear ... and you MUST have this alignment mark if you EVER think this bike will start again

this mark on the left side is for the timing mark if you are using the 'timing dependent' breather valve, which I'm not

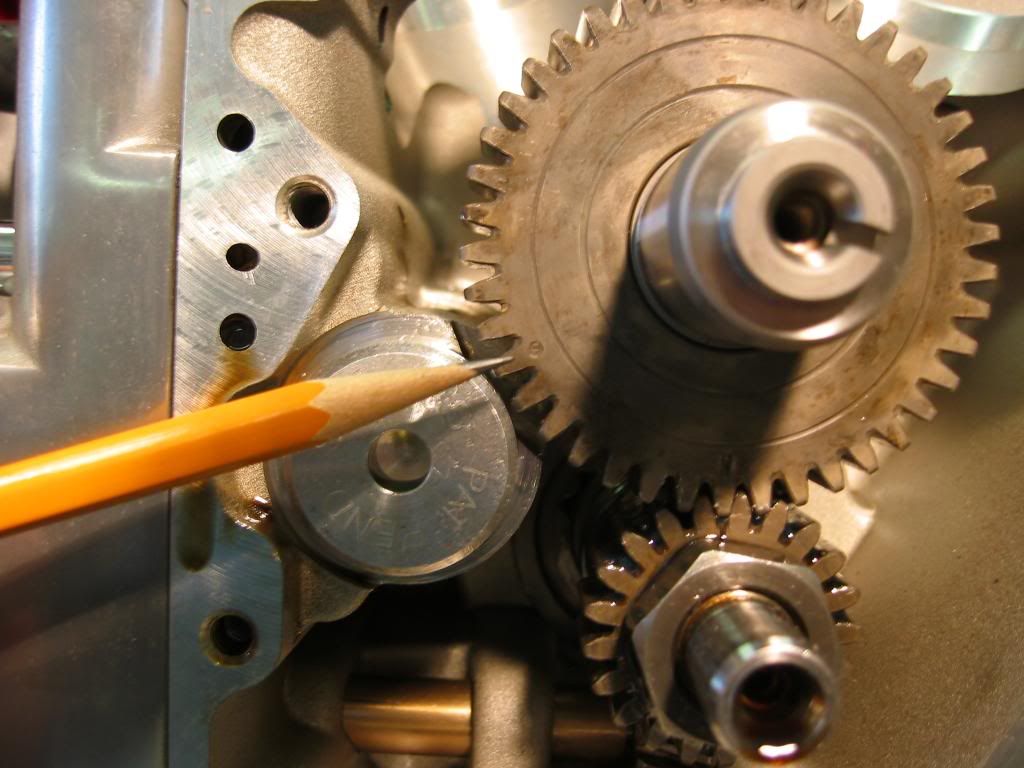

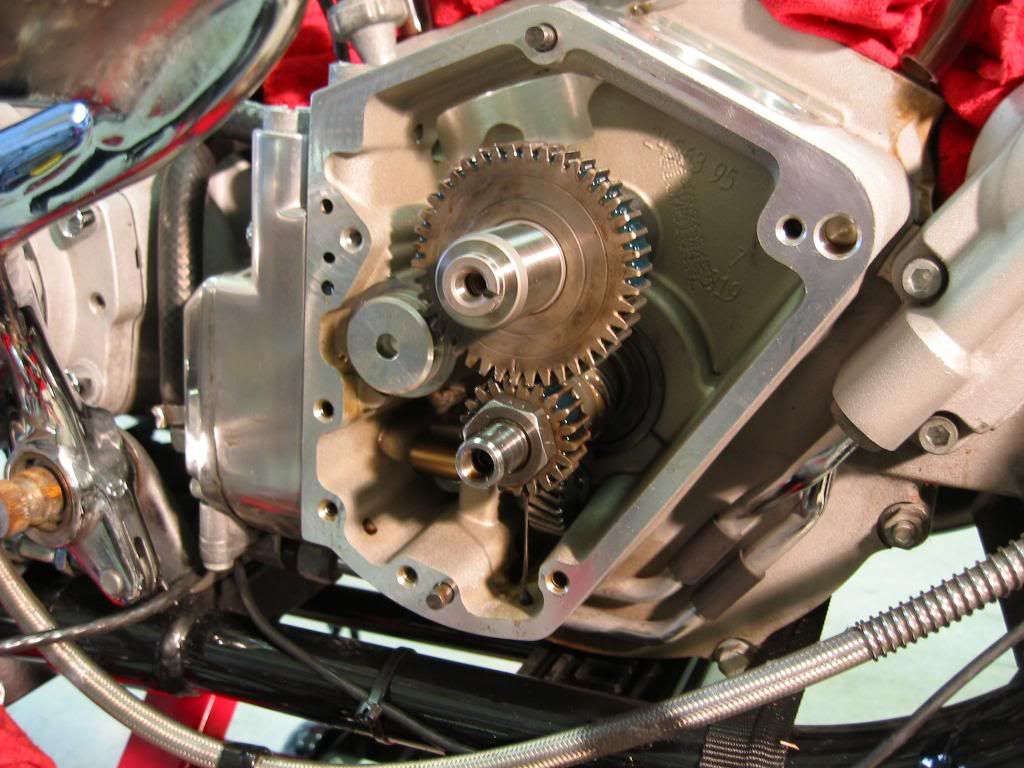

here's the gear chest with the new camshaft, with the orginal cam gear, new torrington bearing and S&S reed valve, all ready to be buttoned up .... dump assembly lube on everything, and then after the cam cover goes on pour 1 pint of clean/new motor oil down through the lifter block hole. This will provide lube to the gears on initial startup before the oil pump gets oil in there.

Author

Topic: Mikey's build of his 2000 FXR4 (Read 76103 times)

Author

Topic: Mikey's build of his 2000 FXR4 (Read 76103 times)