Yesterday I did up her bottom end

most of this stuff is for the 'new guys' that have never done this, but are thinking 'maybe' me too some day ... so the rest of you just enjoy the pics LOL

here's my new lifters soaking in an oil bath (20w-50w) ... they been in this bath for about 3 weeks. The reason you do this is that the lifters have to be filled with oil BEFORE you try to adjust them. You can soak them, the oil will flow into the lifters, or you can use a oil squirt can and squirt the oil in there .... I don't have an oil can and didn't want to spend 10 bucks for one just for this job .... find a plastic dish and put them in there. Be sure to put some saran wrap or something over them ... oil COLLECTS dust and dirt ... you don't want that in your lifters.

you can actually see some of the air bubbles coming up in the oil, you can see my pretty face in there too

Then I set about to clean off the old gaskets from my rocker boxes.

you think that those old paper gaskets aren't 'HARD' / 'TOUGH' ..... look at this razor blade ... it's was NEW when I started

then I set about to clean up the cases where the lifter blocks mount .. some of you should be HAPPY now LMFAO !!!!!!!

then I set about to install the lifter blocks and lifters

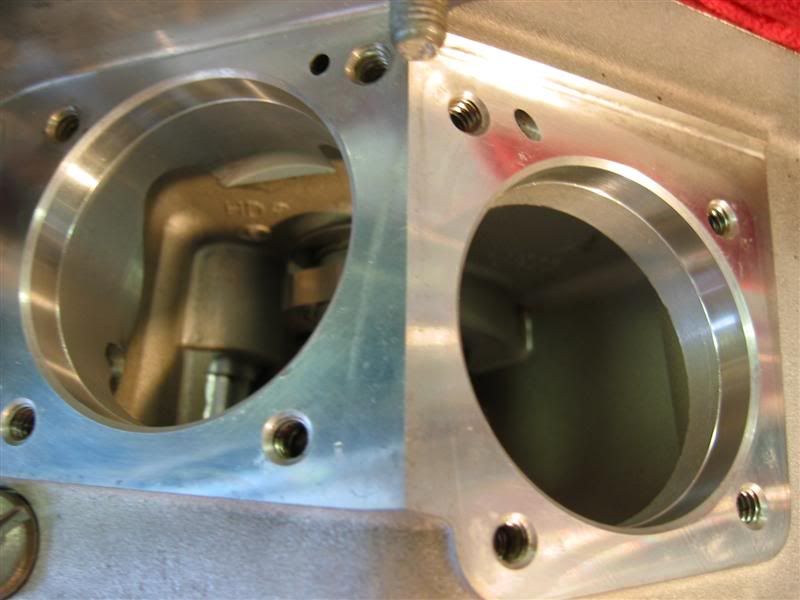

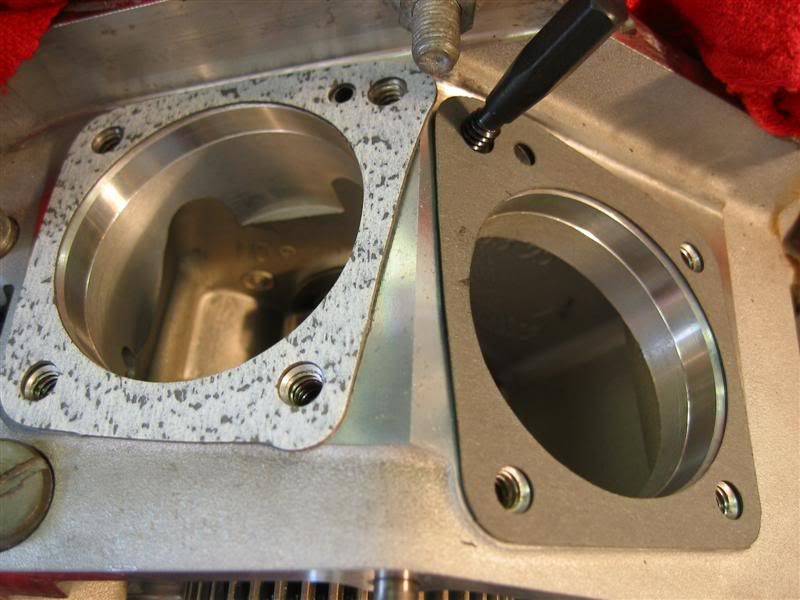

Here you see the block gaskets ... HD stuff, one is silver, one is gray, you CAN NOT mix them up, the silver one goes on the rear cylinder, SIMPLE is as SIMPLE does LOL

for those of you who might not know, you have to use an ALIGNMENT tool when you install the lifters. This insures that the oil passage in the cases are aligned with the holes in the lifter blocks, and more so, that the lifters are aligned properly with the lobes on the cam shaft.

In the above picture you can see the little black alignment tool, it is in this picture only to hold the gasket in place while I was taking the picture.

The way you do it .... put the gasket on the bottom of the lifter block, install the lifters and blocks onto the case, install the alignment tool in the hole next to the oil passage (I use two alignment tools .. in opposite corners) then install the two bolts, torque them down, remove the tools, insert the last two bolts and torque them down

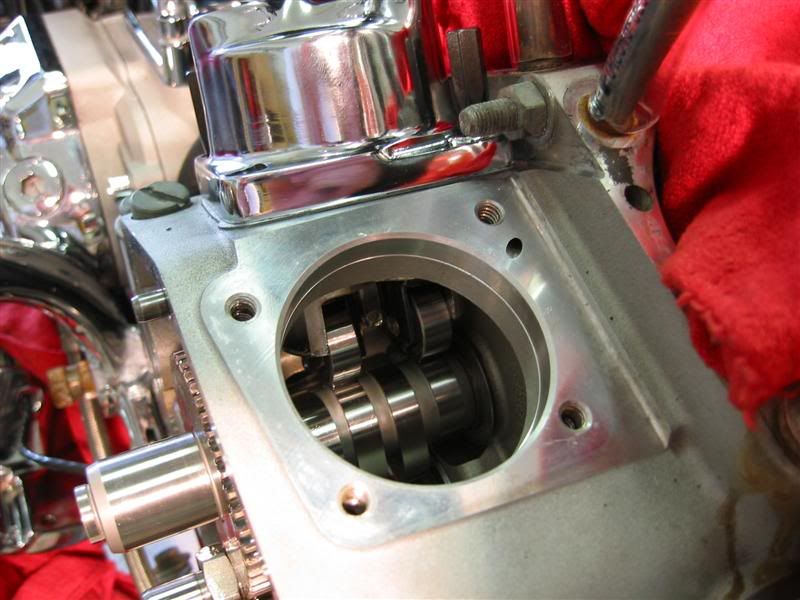

first lifter block installed ..... CHROME !!!!!!!!!!!!!!!!!!

GOES FASTER !!!!!!!!!!!

I did it this way so I could put my fingers in the cam chest to hold the lifters in the blocks while I lowered onto the case. On the second one I just bent a paper clip and hooked it onto the retaining ring lip and pulled the lifters up against the top of the block while I lowered it onto the case ..... didn't want to drop one of them into the cam chest. I closed up the cam chest before I installed the second lifter block because I used that hole to dump 1/4 pint of oil into the cam chest

putting the oil in ... used a funnel because I had the oil in a dish that the lifters were soaking in

putting on the second lifter block... you can see the alignment tool on the lower left of the block .... nice torque wrench huh

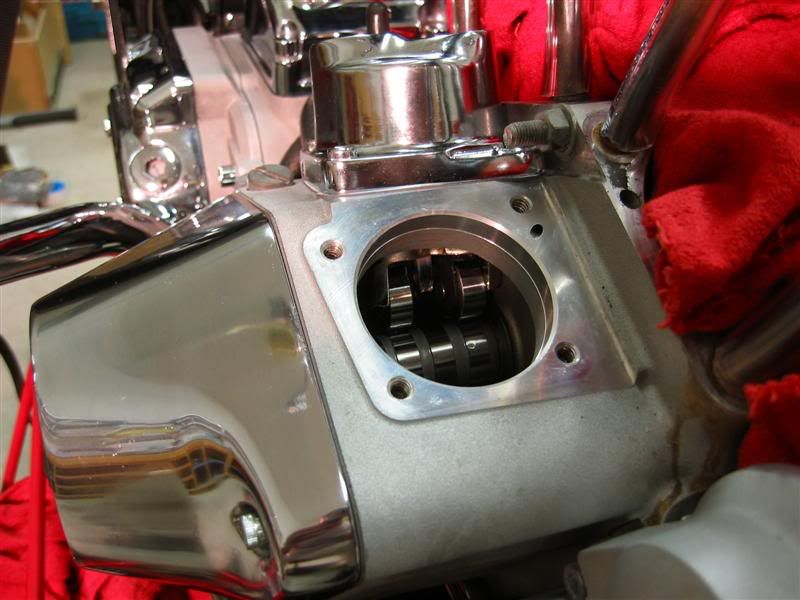

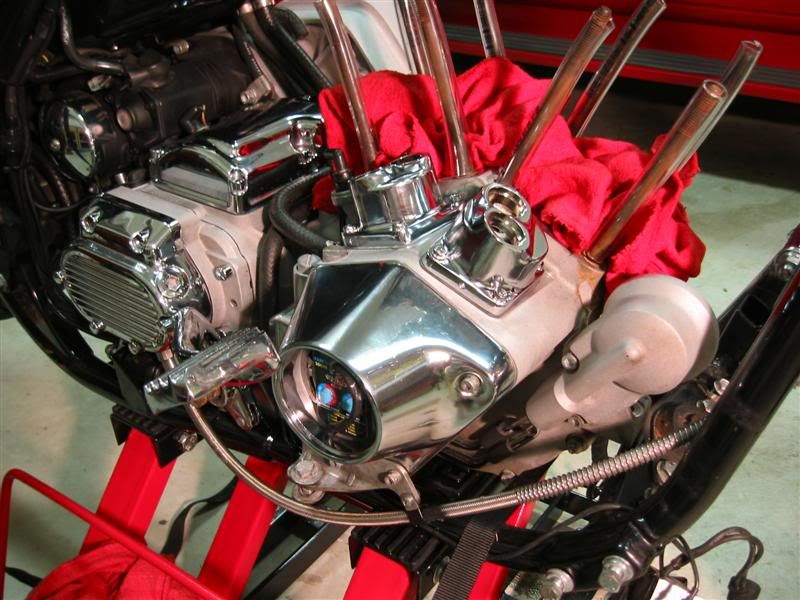

both sets of lifters installed - cam and breather valve installed

Tomorrow, or the next day, when I post up pics you'll see why I did it this way ....

I want to clean up my cylinder studs (YEAH YEAH YEAH ...... I KNOW, I KNOW

) and I wanted to close up the cam chest and cover the lifters cause I don't want any of the debris from that job to get inside .....

Author

Topic: Mikey's build of his 2000 FXR4 (Read 76095 times)

Author

Topic: Mikey's build of his 2000 FXR4 (Read 76095 times)